Find out everything you need to know about the heat sealing process.

¿What is heat sealing?

Heat sealing is the process in which the trays are sealed by applying heat and pressure, thus allowing them to be completely sealed and avoiding air and liquid leaks.

The tray sealers machines are used to heat seal food in trays.

There are different heat sealing systems depending on the product to be packaged: conventional heat sealing, gas flushing system heat sealing, heat sealing with vacuum and gas (MAP - Modified Atmosphere Packaging), heat sealing with Skin Pack ISO ( in trays) and Skin up heat sealing (flat cartons).

¿What type of food we can package?

- Meat

- Fish

- Fresh vegetables

- Fruits

- Ready meals

- Dairy products

- Alternative protein

¿What are its advantatges?

- Keep the freshness of food and the ready meals.

- Prevent the air entrance to the trays.

- Extend the shelf life (gas flushing system, MAP or SKIN)

- Guarantee the food safety.

- Help its transport by avoiding spillages.

- Facilitate its storage.

¿What solutions does Reiserpack offer?

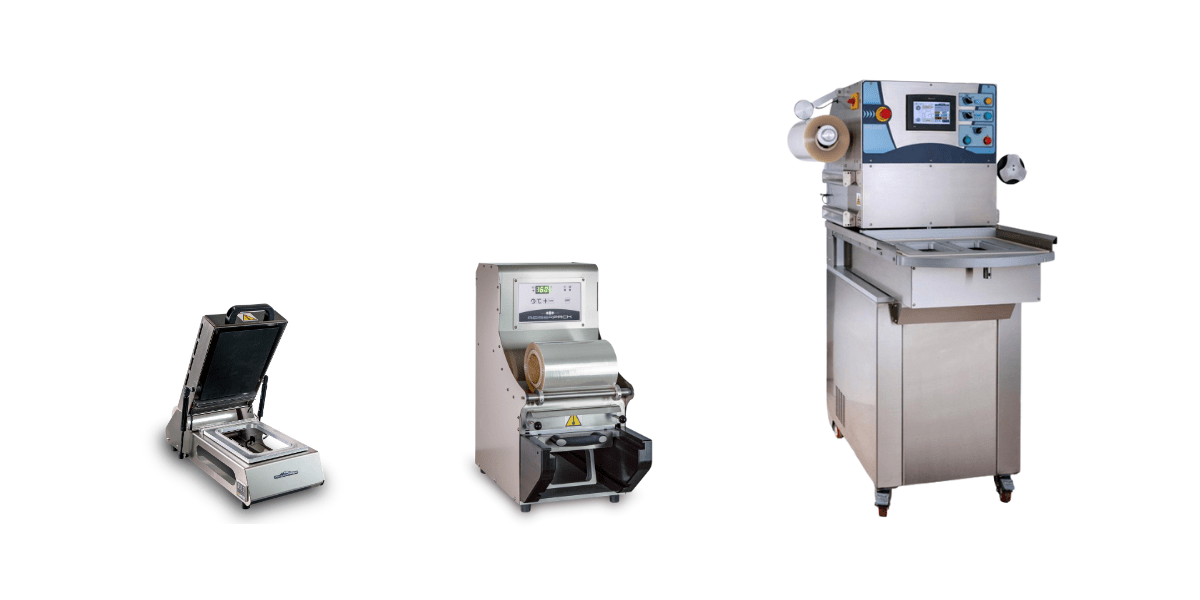

At Reiserpack we have 3 ranges of tray-sealers machines, for all types of business, from small business to large chains and food industries: butcher shops, fishmongers, producers-breeders, workshops, caterings, professional kitchens, supermarkets, take away and restaurants.

Each tray sealer machine that we manufacture is adapted to customer's need, depending on product, tray and heat sealing system that wants to be used.